The recent surge of interest in composting waste materials has led to new regulations to control contaminants and ensure environmental and human health and safety. Since regulations usually define the maximum total concentration of certain contaminants (e.g., heavy metals) permitted in the finished compost, facility managers must develop an appropriate testing program to ensure quality control and compliance.

Contract laboratories that analyze for contaminants should have an established quality assurance program for their chemical analyses, and a composting facility manager should obtain documentation that this program is adequate and being followed. But this is only one step of a multi-step process, and the facility manager's responsibility does not end here.

Accurate and precise analyses depend on a sequential chain of events, from the careful planning of a quality assurance program and selection of a large number of randomly selected samples to proper sample handling, chemical analysis, and data reduction and reporting. The quality of information generated at each step is entirely dependent on that of the previous steps. Clearly, if inappropriate samples are collected, even highly accurate chemical analyses will not produce useful information about compost quality. If sampling and testing methods are not adequately recorded or reported, assuring the quality of the information generatedand thus, the quality of the compost producedis impossible.

Since sample collection, handling, storage, and shipping are generally conducted by facility personnel, a quality assurance program that addresses these steps must be developed by each facility. The key steps in developing such a program are discussed below.

This fact sheet can not cover all the issues in detail. For example, although this fact sheet focuses on municipal solid waste (MSW) composts and heavy metal contamination, the issues raised are relevant both to other types of composts and to other measurable compost characteristics such as toxic organic chemicals and plant nutrients. Hopefully, however, the examples and references provided will serve to stimulate greater attention to the tasks required to assure that compost is a consistently high quality product.

Defining Data Collection Objectives

To accurately assess quality and control costs, data collection objectives must be defined precisely. Different professionals will have different objectives. Researchers, for example, may want to determine the speciation (precise chemical form) of metals since such information is critical for determining the environmental fate of metals. Regulators, who require data to establish appropriate compost composition standards and ensure compliance, need to know the variability of contaminants.

Facility managers need data to establish sampling plans and achieve quality control. Their objectives will include optimizing the composting process to produce high quality compost at the lowest possible cost and to meet product standards. Generating the data needed to set standards or to establish a quality control program may require more intensive sampling than will be required for routine screening.

Compost users may have product quality concerns that are not covered by regulations. Physical characteristics such as water-holding capacity, for example, may be critical for some applications of compost. Customer objectives should also be addressed by a quality assurance program.

Some objectives will be shared by these different groups. These include assessments of compost nutrient content and availability, compost maturity, soluble salts, toxicity to plants, organic contaminants, trace metals, and inerts such as glass and plastic film.

Development of a Quality Assurance Plan

Quality assurance plans are being developed for some large-scale composting facilities and some states are beginning to provide regulatory guidance in this area. The Solid Waste Composting Council is also developing general guidelines that will propose limits for compost stability, soluble salts, pathogens, pH, heavy metals, inerts, and film plastic and will recommend sampling protocols, analytical methods, and other elements of a quality assurance plan.

While these and other resources are useful, quality assurance plans must be tailored for each facility. The development of a quality assurance plan should include consultation with all parties involved in the program and an assessment of the objectives and needs of individual facilities.

Key Steps in a Quality Assurance Program

Ensuring Proper Sample Collection

Compost sampling is often a major source of uncertainty in compost test results. In fact, as analytical techniques improve, controlling sampling error frequently becomes the limiting step in assuring compost quality.

Because of the great variety of materials in feedstocks, MSW compostsand the distribution of contaminants within the compostscan be highly variable. Understanding this variability within and among compost batches is essential for establishing appropriate sampling methods and predicting the percentage of composts that will meet a given standard.

Without an adequate sampling plan, many questions about compost quality remain. If a single sample or a single composite sample is taken from a batch of compost, how well does this sample characterize the compost? If the concentrations of metals in this sample exceed the regulatory limit, must the whole batch be disposed of? How similar would the metal concentration be in another sample from the pile?

Several aspects of sample collection -- random sampling, ensuring an adequate number of samples, determining the frequency and timing of sampling, and sub-sampling -- are crucial to answer such questions and ensure valid test results.

Random sampling: Since compost feedstocks may vary greatly in the waste material they include, potential contaminants will not be evenly distributed when the raw material enters the facility. Further, particular contaminants may be associated with certain size fractions of the waste stream and thus, the resulting compost. For example, lead in compost produced from leaves or grass clippings is mostly in the form of fine dust deposited from air emissions. Hence, it is not surprising that a study of MSW compost demonstrated that metals, particularly lead, were most common in the 0-10 mm fraction. Finally, mixing and leaching may concentrate potential contaminants in particular regions of a batch.

For these reasons, it is crucial that multiple samples be collected from randomly selected locations within the batch. "Random sampling" means that every location in the batch has an equal chance of being sampled. Reports that "representative samples" were collected are common, but are not an adequate substitute for random sampling. In fact, the term quot;representative sample" should serve as a warning for those interested in quality assurance. All too often, it is used to mean a grab sample taken either intentionally from a certain region of the pile or windrow or selected haphazardly, but not selected randomly. Without random sampling, no assessment of the bulk material is statistically valid, no matter how carefully the subsequent chemical analysis is performed.

Ensuring an adequate number of samples: Taking enough samples to accurately assess the m concentration of a particular contaminant is one of the most neglected aspects of quality assurance programs. Given the heterogeneous nature of MSW compost, there can be considerable variation among samples from a single windrow, and a single sample might fall either above or below a regulatory limit simply due to chance.

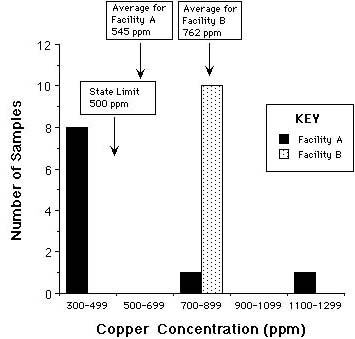

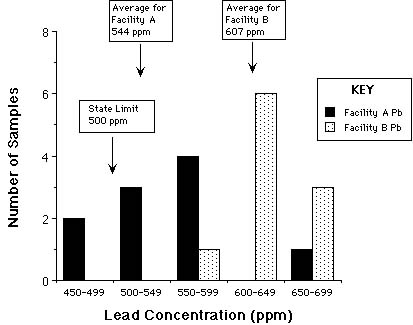

In a recent survey of two operational MSW composting facilities, in Delaware and Minnesota for example, we found that the metal concentration varied considerably among ten randomly selected samples from single batches or windrows (see Figures 1 and 2). While the copper concentration, for example, was extremely homogeneous in the batch from one facility, it varied from 300-1180 parts per million in the second. These data show the need for taking an adequate number of samples and for designing a program specific to the particular facility.

Figure 1.

figure 2.

Measuring the variability in concentration of contaminants is particularly critical when the levels are near regulatory thresholds. in both delaware and minnesota the maximum allowable concentration for both copper and lead in class i composts is 500 ppm. the average concentrations of both lead and copper in the 10 samples exceeded 500 ppm for both metals at both facilities, but at one facility many of the samples tested fell below that regulatory limit. similar variations were found for lead, zinc, nickel, and other metals.

Unfortunately, no simple answer exists to the question "how many samples must be collected to assure an accurate assessment?" in the example above, calculations of the number of samples required to assess the true mean concentration for copper (with a 95% confidence level) ranged from 3 at one facility to 313 at the other.

The number of samples needed depends on the accuracy required, the heterogeneity of the feedstock, and the degree of mixing during processing. each facility should determine the number of samples required as part of its quality assurance plan.

Frequency of sampling: In addition to variability within a batch of compost, one must also expect variability among batches of compost. Feedstocks may vary considerably throughout the year, resulting in changes in contaminant levels. Thus, decisions must be made about the appropriate frequency of sampling. Is each batch of compost to be analyzed, or are samples to be collected only periodically throughout the year? The answer can only be rationally determined by testing the variation of potential contaminants over time to assess the variation present and design an optimal sampling regime.

Timing of sampling: Decisions must also be made about when during the composting process the compost is to be tested. As the organic matter in the compost continues to decompose over time, the concentration of other components such as trace metals will increase on a dry weight basis.

Alternately, the data may be presented on an ash basis, that is, as a proportion of the weight of the non-organic component. Since this component will not decompose, this approach permits contaminant measurements to be made at any time in the process.

Sub-sampling: Because of the variability within compost samples, analytical laboratories must pay special attention to sub-sampling. As with the original sample collection, multiple sub-samples must be collected from randomly-selected locations. Whenever samples are taken from a larger batch for analysis, homogenization (e.g., mixing, grinding) is critical and verification of the effectiveness of such homogenization is needed.

Protocols for Sample Storage and Transport

Samples must be stored and transported such that no materials are added or removed that alter the analytical result. Generally, samples should be collected in clean plastic containers, refrigerated but not frozen, kept in the dark, and analyzed within a few days of being sampled. Appropriate protocols for sample handling are dependent on the objectives and can be particularly stringent for analyses of volatile chemicals and micro-organisms.

All samples should be permanently and unambiguously labelled, and a permanent record of all pertinent data be kept in a bound volume. The chain-of-custody for all samples should be specified, and it is useful to have one person supervise the entire process. (Details of appropriate methods can be found in the EPA manual, see box.)

Selecting Appropriate Analytical Methods

Since regulations are based on total metal content in the compost, complete extraction of the metal from the sample is essential if compost quality is to be assured. One way to measure extraction efficiency is to use certified reference standards. A "reference standard" is material in which the concentration of metals or other parameters are known, enabling laboratory analysts to validate the accuracy of their analytical methods. Unfortunately, no such standards currently exist for MSW compost. The most appropriate substitute is probably an industrial sewage sludge standard from the National Institute of Standards and Technology (NIST BLR 146).

Such standards should be included in each laboratory procedure, along with appropriate spikes (known additions of the substance being analyzed) and blanks ("samples" without the substance being analyzed, used to test for contamination). The results of all analyses of standard materials should be reported along with other results to validate the data.

Unfortunately, such quality assurance data are rarely reported. A study of metal concentrations in MSW composts produced at several North American facilities, for example, reported a high degree of variation in results from different laboratories. Routine use of reference standards can help validate analytical methods and avoid such disconcerting discrepancies.

Proper Data Record-keeping, Analysis, and Reporting

The measurements used to validate results, protocols used in sampling and testing, and details of the statistical methods employed should be reported along with the primary data so that the strengths and weaknesses of the data can be determined independently by the reader. The American Chemical Society has published useful guidelines for the evaluation of environmental data. The Environmental Protection Agency's (EPA) two volume set, "Test Methods of Evaluating Solid Waste Physical/Chemical Methods," presents useful statistical background as well as laboratory protocol and discussion of sampling issues.

Controlling Costs

Finally, the costs of sampling, analysis, and other aspects of a quality assurance program must be controlled. If the costs are prohibitive, the program will be difficult to implement. On the other hand, compost facility operators must be aware that consistent production of high quality compost is critical to the success of all composting operations and that verification of compost quality will incur some unavoidable costs.

Although the following list is not comprehensive, it covers the most critical aspects of quality assurance for most metals.

Recommended Sampling and Laboratory Practices to Assess the Trace Element Concentration of MSW Compost Products

· Obtain multiple composite samples from randomly selected locations within a pile or windrow.

· Use plastic containers for sampling and storage to avoid contamination; use field blanks ("samples" without the substance being analyzed) to test for such contamination during sample storage, transport, and processing.

· Analyze replicate subsamples of each composite sample, being careful to mix samples thoroughly and reduce particle size as needed.

· Use National Institute of Standards and Technology (NIST) or comparable standard reference materials to determine the accuracy and precision of the digest/analysis technique.

· Add a known concentration of the element of interest to compost digest solutions to check for potential matrix interferences.

· Carry reagent blanks throughout the digest and analysis protocols.

· Report metal concentrations of the compost on a dry weight basis.

· Report the ash content of samples.

· Report all quality assurance data along with sample data so that data quality can be independently evaluated.

Note: Additional care must be taken with some metals such as selenium and

mercury that may volatilize during processing and for organic compounds that may

volatilize or undergo chemical transformation prior to analysis.

Useful Reference Materials for Developing Compost Quality

Assurance Programs

American Chemical Society. In

Analytical Chemistry.52:2242-2249. 1980. Guidelines for

the acquisition and evaluation of environmental data.

Solid Waste Composting Council, 114 S. Pitt St., Alexandria, VA 22314. Guidelines for quality assurance, including proposed limits for compost stability, soluble salts, heavy metals and other parameters. In preparation.

U.S. Environmental Protection Agency. Office of Solid Waste and Emergency Response. Test Methods for Evaluating Solid Waste. Field Manual SW-846. 1986.

Woodbury, Peter B. and Vincent T. Breslin. In Biomass

and Bioenergy (Vol. 3, Nos 3-4, pp. 213-225, 1992). Assuring

Compost Quality: Suggestions for Facility Managers, Regulators,

and Researchers.

References

See the fully referenced article in a special 1992 issue of Biomass & Bioenergy (Vol. 3, Nos 3-4, pp. 213-225, 1992), from which this fact sheet is extracted. A copy of that journal containing 11 articles on MSW composting can be obtained through the Composting Council, 114 S. Pitt St., Alexandria, VA 22314..

Published by the Cornell Waste Management Institute, Dept of Crop and Soil Sciences. 607-255-1187.

The research for this paper was supported in part by funds provided by Clark Engineers and Associates and the State of New York through the NYS Energy Office. Their support of this work is gratefully acknowledged. Thanks to Stephen Ebbs who carried out the massive literature search necessary to the preparation of this fact sheet. The authors are solely responsible for the papers' contents, although they gratefully acknowledge helpful comments and discussion with numerous colleagues.

Special thanks to Margo Hittleman who assisted in developing

this fact sheet from the longer technical paper.

|

|---|

This page was created in 1996

Cornell

Waste Management Institute ©1996

Dept of Crop and Soil Sciences

101 Rice Hall, Cornell University

Ithaca, NY 14853-5601

cwmi@cornell.edu